FUNCTIONAL PROTEINS

For Alternative Foods.

Microorganisms (e.g., fungi, yeast, microalgae), insects and cultures (lab-grown) are vital tools to produce alternative proteins to mimic animal-sourced meat or fish.

Microorganisms (e.g., fungi, yeast, microalgae), insects and cultures (lab-grown) are vital tools to produce alternative proteins to mimic animal-sourced meat or fish.

Premas is fast emerging as a front runner in this domain.

Recombinant proteins, enzymes, flavors, sweeteners, etc, for alternative food applications, GMO proteins, milk proteins, gluten proteins for assessing food allergies, proteins for food industries, and many more.

Alternate Food Proteins From Lab to Commercial

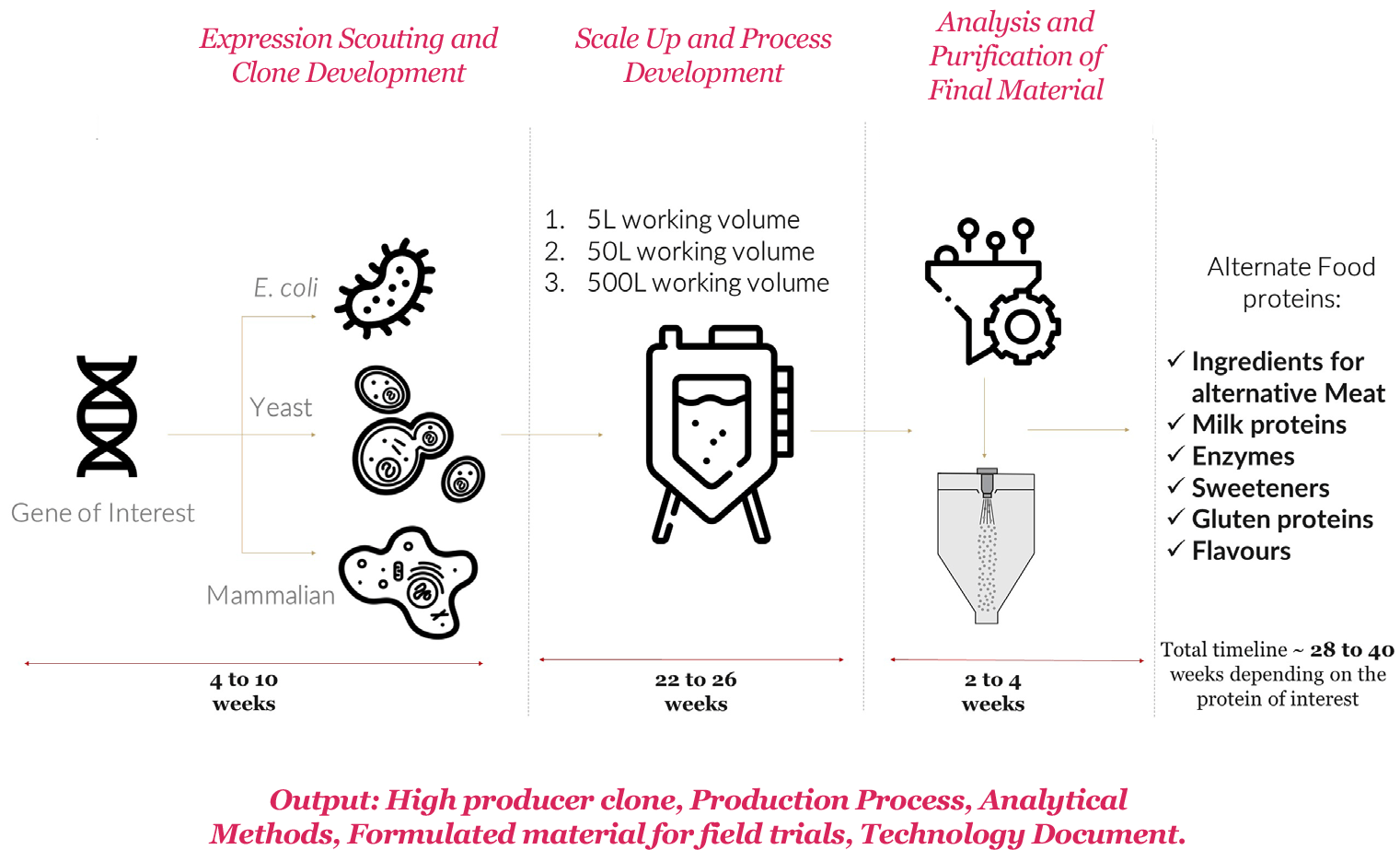

Premas has the capability to generate high-producer strains and clones in yeast and microbial strains. While most of our work in the food sector has been focused on yeast, we have also used E coli for specific growth factors and allergens. Premas has access to a wide range of cloning and expression vectors to obtain a high expression scout derived clones. We perform rapid screens to arrive at host options.

A. Yeast

Saccharomyces cerevisiae | Pichia pastoris | Strain Development

B. Microbial

E coli | Bacillus | Custom Strain Development

A typical screen will consist of screening hosts, vectors, growth media, growth parameters, time, inducer concentration, induction time and temperature, feeding strategies.

As several clones are selected, spent media analyses are used as a guide for improving the yields along with feeding strategies.

For difficult-to-produce proteins, we can engineer an entirely new strain with defined properties. Premas has generated several such strains to enable complex folding options, protein complexes (more than 1 protein in a single host), etc.

2 X 75 Litres Fermenters

At Premas, we have multiple levels of process optimisation and development. We take customer processes as input steps and further collaborate to improve the yields. We utilise our crucial understanding of the protein product and the unit operations to minimise losses and improve yields at every step.

Starting at 0.5L to 500L fermentation, we develop the process to suit the commercial manufacturing scales, along with a concomitant at scale, development of the clarification (broth) or lysis to release the product, and high-performance purification steps.

Products are either supplied in liquid form, lyophilised or spray-dried. Premas has options for all three. The batches are released per the specifications of the product, and the assays can be tech transferred to Premas or developed internally.

2 X 700 Litres Fermenters

Premas has the capacity to produce kilograms of material for field trials, testing purposes, blending and other applications.

2 X 700 Litres Fermenters

Premas Biotech has capacities to manufacture kilograms of material for commercial supply.

For commercial manufacturing, Premas has strategic partnerships with commercial manufacturing units and help in tech transferring the process to them.

Food proteins are complex biomolecules that contribute to food's nutritional and functional properties. Accurate analytical characterisation of critical quality attributes is considered crucial for the quality and safety of the product.

At Premas, various techniques are utilised to certify the final product's identity, purity, and contaminant loads. The test protocols and assays are:

2 X 7 Litres Fermenters

2 X 7 Litres Fermenters

Batch Centrifuge

Batch Centrifuge

Spray Dryer

Spray Dryer

Akta Process (Cytiva)

Akta Process (Cytiva)

ChromXact Chromatography Column

ChromXact Chromatography Column